Chlorine Monitoring

This is a difficult and often misunderstood measurement to make for industrial water treatment.

Here’s why: Chlorine in solution is a weak acid, so the concentration of active chlorine is affected by changes in pH. Furthermore, if Ammonia is present, chlorine reaction time changes. Each application is different and may require the use of ORP measurement, free-chlorine, combined chlorine or total chlorine measurements. We can help identify the most straightforward sensing technology for you.

ORP Measurement

ORP measurement has been used successfully for free-chlorine monitoring in wastewater treatment, cooling tower control, and water for disinfection. It is effective in high-maintenance areas where solids build-up can cause fouling of membrane-type chlorine sensors. The relationship between ORP and chlorine at various pH levels has been well-documented.

Unlike membrane-style specific-ion chlorine sensors, ORP sensors are more robust, lower-cost and coating-resistant. ORP electrode surfaces can be cleaned with soap-and-water or mild acid solutions. There are no membranes to replace. Differential ORP sensors are available that have replaceable junctions designed to extend sensor life. They may be used in-line or submerged in a tank.

As stated above, chlorine concentration is affected by pH changes. pH of the solution needs to be controlled prior to taking a chlorine measurement. The pH should be stable, not fluctuating more than 0.1 to 0.2 pH units.

Careful: ORP Is Non-Specific!

Unlike amperometric or colorimetric sensors that are chlorine ion-specific, ORP sensors are not. They output a more general, “millivolt” reading, as opposed to “ppm chlorine”. However, the results are more reliable at very low chlorine levels. Variables in the process stream must be eliminated to ensure accurate chlorine correlation. Stabilized pH is key when using ORP to control chlorine feed. Here’s why: An ORP sensor measures all oxidation and reduction reactions in solution. The assumption in ORP-chlorine monitoring is that the addition of the chlorine is the most dominant reaction in the solution. By eliminating other variables in the process, this principle will hold true. An example of this is ferric chloride, often used as a coagulant. If this is added upstream of the chlorine addition, a clarification process should be used.

Examples of ORP Residual Chlorine Measurements in Sodium Bisulfite Addition

- Industrial Reverse Osmosis Systems

Sodium bisulfite is added to the water to remove chlorine that can damage expensive membranes. ORP sensors are more robust than amperometric or colorimetric sensors and do not require sampling, which can delay response time of the controller.

2. Dechlorination

Chlorine is used in the cooling tower and process wastewater disinfection. Before leaving a facility, the water must be dechlorinated. This prevents harm fish and wildlife living or feeding in the lake, river, stream, etc. For wastewater chlorine monitoring, an ORP sensor is recommended for mounting in the wastewater stream, rather than sample tubing. Sample tubing in wastewater applications is more prone to bacterial build-up and clogging than clean water applications because the chlorine level is already low. Hence, sensor maintenance is reduced.

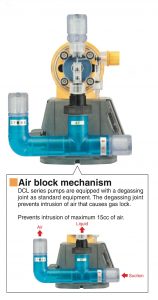

Consider a Specially-Designed Chlorine Feed Pump

Pump Tank Systems are also available.

Questions? We can help. Contact Murphy & Dickey. 630-655-1080