Instrumentation & Pumps

If you need help choosing the right instruments and pumps for your wastewater treatment needs or are looking for a simpler, more efficient system to replace your current equipment, you’ve come to the right place. We will ask about your specific application, including your treatment process and physical installation. This will help our experienced engineers determine the right system for you.

Equipment Ordering

Ordering measurement instrumentation or pumping equipment can often become a confusing process. Murphy & Dickey’s customer service team is trained to help you through that process. We double-check your application with the engineering recommendations to ensure that all the details that will make your system work are included. Next, we coordinate with the equipment manufacturers to make sure your measurement and pumping solutions are correct and delivered when you need them.

Company History

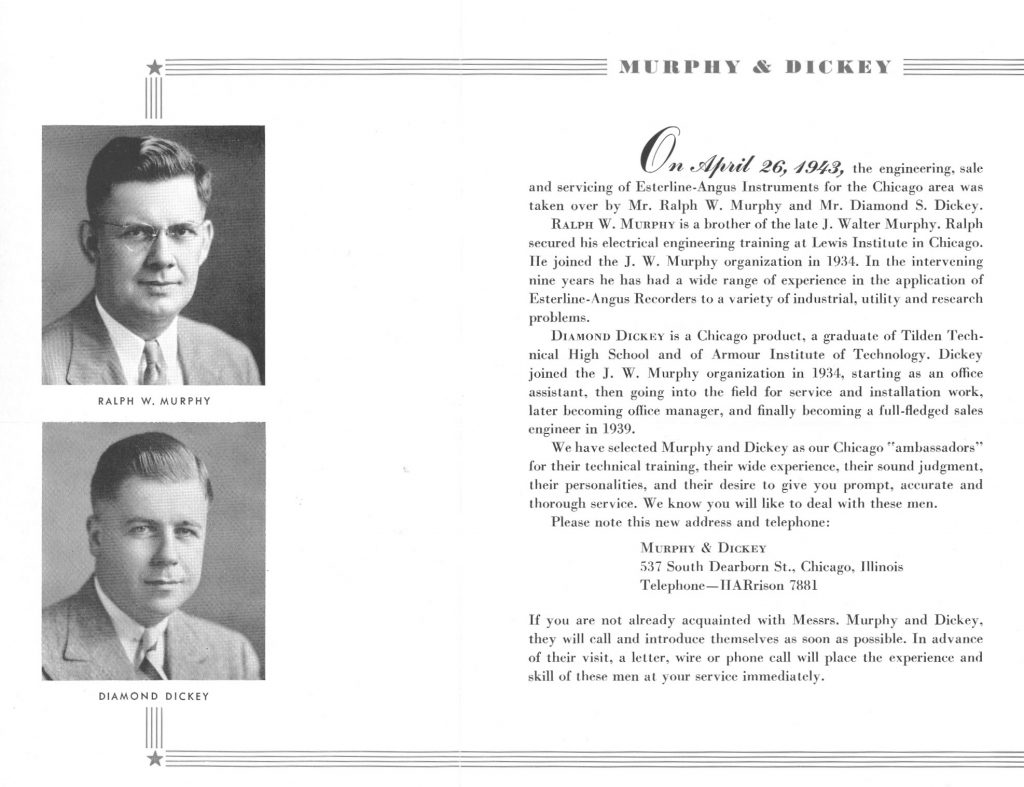

Murphy & Dickey was started by Ralph Murphy and Diamond Dickey in 1943, in downtown Chicago. Originally, the company provided electrical testing and process recording equipment to local manufacturing and power generation facilities.

Ralph Murphy & Diamond Dickey, 1943

In the 1970’s, under the direction of Jim Fell and Mark Potter, the company moved to the Western Suburbs. For the next 25 years, M&D specialized in instrumentation for water monitoring, gas analysis, and temperature control. In the 1990’s, pumps, mixers, and water treatment equipment were added.

Jim Fell, Diamond Dickey, Mark Potter @1970

Since 1999, Tom Fitzpatrick and Mark Ostrowski led M&D, with a new team, in our company tradition of treating others as we want to be treated.

M&D team continues to solve applications for instruments and pumps for water treatment in industrial and municipal facilities. Our engineers are also trained in the application of fire and gas detection systems, used in industrial, municipal and commercial locations.

Tom Fitzpatrick, Jim Fell, Mark Potter, Mark Ostrowski, 1999

Murphy & Dickey Team, 2018